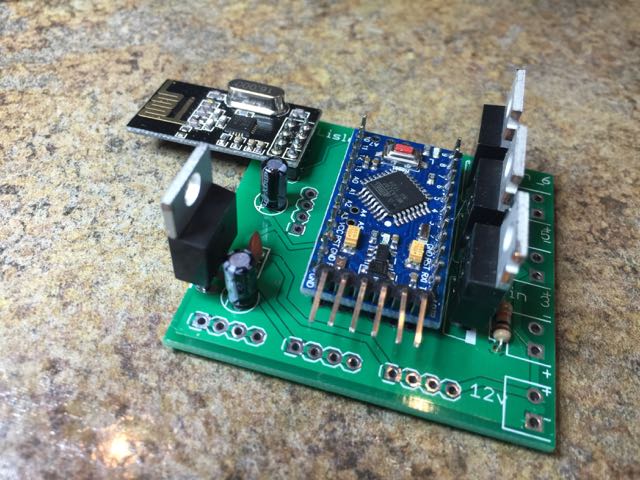

I’ve updated the printed circuit boards for my IoT projects. These boards are 5×5 cm and intended to be used in a variety of IoT applications. They include the following features:

- Switch from linear voltage regulator to buck regulator.

- The linear regulators used on my previous boards were getting quite warm as a result of converting the RVs +12 volts to +5 or +3.3v. I found some inexpensive variable voltage bucking regulators for about $1 each. These are marked “D-Sun”, readily available on Amazon.com, and they work well.

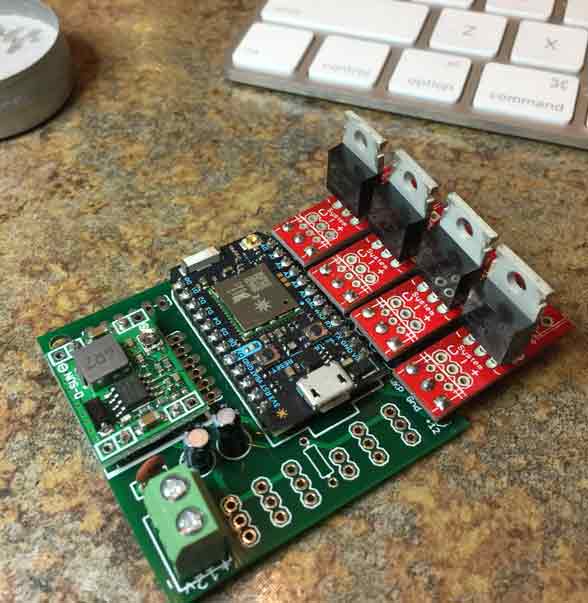

- Provide direct pin-outs to LED driver boards.

- I’ve provided 4 sets of PWM pins that can interface directly with the Sparkfun 12959Â MOSFET LED driver boards. I’ve positioned the pins such that standard header pins can be used to attach the boards instead of wires. I’ve gone back and forth about integrating the functionality directly, and finally concluded that the space used by the MOSFET and screw terminals was better pushed off onto small extension boards. Up to four of these can then be optionally added as needed. Sparkfun sells these for $4 each, so it’s sort of a no brainer. Putting them onboard would force me to moving to a larger 10×5 cm board, and only save a couple bucks.

- Both 3.3v and 5v supplied

- I’m using a 5v regulator to provide power to the Photon. It then has a 3.3v regulator for itself, and can provide 3.3v @ 100 mAÂ to other sensors, etc. Since most of the Photons pins are 5v tolerant, this enables using both 3.3v and 5v sensors.

- Provide groups of pins for ease of connecting other devices

- To simplify adding additional sensors such as DHT11 temperature sensors, I’ve provided groups of pads that provide a GPIO, power, and ground. Some are 5v, and some are 3.3v. I was careful to ensure that the GPIOs provided with the 5v power groups are in fact 5v tolerant. These are great for things like PIR motion sensors, various switches, and so forth.

So after checking that the first batch of 10 boards work as intended, I’ve ordered another 10 and am in the process of replacing most of my existing controllers with these. While the Photon costs substantially more than the previous Arduino Pro Mini and RF24 radios, the ease of programming over the air combined with their robust design (5v tolerant pins, super stable operation) and included Particle.io support make these worth it!

I’m currently using my Echo and Dot to control these, but recently got AVS running on my Raspberry Pi and may throw that into the mix also.

If anyone is interested in using these boards in your own projects, post your request in the comments and I’ll provide links to the Eagle files so you can have boards made yourself. If you don’t mind waiting about 6 weeks, you can order these from itead.cc for $13 total for 10 boards. If you’re in a hurry, DHL shipping increases the total cost to about $26 total for 10 boards that arrive in less than 2 weeks. I ship with DHL for the first batch, then use the cheaper shipping to get more while I work with the first batch.

Note: I’ve now posted the Eagle files on Github.

At this point I’ve installed about a dozen Arduino Pro Mini based controllers in my RV. These are very inexpensive, about $2 each, but suffer from several limitations:

At this point I’ve installed about a dozen Arduino Pro Mini based controllers in my RV. These are very inexpensive, about $2 each, but suffer from several limitations: In my usage case, I’m mounting these things above ceilings to control lights, and behind wall switches to read and broadcast switch state. This means every time I need to change or debug them, I have to open up the wall, which means removing the switch plate and switch or lamp fixture to get to them.

In my usage case, I’m mounting these things above ceilings to control lights, and behind wall switches to read and broadcast switch state. This means every time I need to change or debug them, I have to open up the wall, which means removing the switch plate and switch or lamp fixture to get to them.