I’ve started playing with the LightBlue Bean as a part of my RV Automation project. This $30 part combines a low power, 3.3v Arduino board with Bluetooth LE, several sensors, and an attached 3.3v watch battery. This means that it can be used to do a lot of jobs without any connections whatsoever, and it can talk with an iPhone over BTLE.

I first heard about this part from a github article that my friend Sean wrote. It’s a well written article, fun to read, and I recommend that you read it. Thank you, Sean.

What Can I Do With A LightBlue Bean?

Using Bluetooth

I think the best thing about this part is the built-in blue tooth.

iPhone Connection

I expect the bean to be a bridge from my iPhone to other Arduinos. BTLE makes it very simple to interface to an iOS device using

iBeacon

I may be able to take advantage of the fact that any BTLE device can be configured to act as an iBeacon. This will enable the iPhone app to determine proximity to it. This leads to all sort of automation possibilities:

- Turning nearby lights on/off

- Disabling security system when near

- Unlocking doors

Of course, security will be important, so I’ll have to consider carefully the use of a passcode or some other system to prevent allowing unwanted access if my phone is stolen.

Using the built-in 3 axis accelerometer

The bean also includes a built-in 3 axis accelerometer. This means that it can detect motion in any direction.

Security System

One of the shortcomings of living in an RV is that it moves when walking around inside of it. I’m planning on turning this into an advantage, and use this as a component of my security system.

Leveling

The accelerometer will be used to help me level the RV when parking. Since gravity is indistinguishable from acceleration, it makes a great way to check for level. I’ll need a way to calibrate the level settings after mounting the bean, and I’ll want to convert the accelerator readings from Gs to angle for display on my iPhone.

Door Motion

Another possible application, but one I don’t plan on using at this time, would be to mount the bean to a door. Since it’s battery operated, this could be as simple as just sticking it onto a door.

Using the Temperature Sensor

This is a no-brainer, but does require me to think about where I mount it. Do I want interior or exterior temperature readings?

Using the RBG LED

Status Display

I expect to mount the LED such that it can be used for displaying status of some sort. It can display any color, and be dimmed and/or blinked, allowing for a large range of indications.

Interfacing with Other Arduinos

I expect the bean to be a bridge from my iPhone to other Arduinos using inexpensive RF24 parts. These can be purchased for under $2 each.

Replacing the Battery

I expect to connect it to my RVs 12v system eventually, so I don’t have to keep replacing batteries. This will require a 3.3v regulator. The LD1117v33 is available from Amazon for under $2.

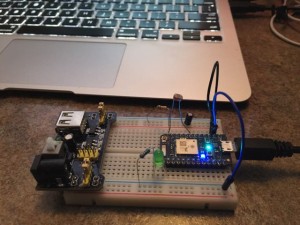

OMG, this $19 part is amazing! We’re talking immediate WiFi connectedness. The team at Particle.io has done an amazing job of providing a web-based Arduino environment. Connection to their servers was super easy, and the tutorials provided on their website will get you up and running quickly.

OMG, this $19 part is amazing! We’re talking immediate WiFi connectedness. The team at Particle.io has done an amazing job of providing a web-based Arduino environment. Connection to their servers was super easy, and the tutorials provided on their website will get you up and running quickly.